The Versatile Applications of Gypsum Across Multiple Industries

Gypsum, a naturally occurring mineral composed of calcium sulfate dihydrate, has long been an integral part of various industrial processes. After being extracted from quarries or mines, gypsum is ground and heated to produce a fine powder. This powder is a key component in numerous sectors due to its versatility and ability to serve different functions. From construction to agriculture and healthcare, gypsum plays a crucial role in improving product quality, enhancing efficiency, and contributing to the overall development of these industries. In this article, we will explore the wide-ranging applications of gypsum in various industries and highlight its importance in shaping modern practices.

Gypsum in Construction: A Building Block of Modern Architecture

One of the most prominent uses of gypsum is in the construction industry. Gypsum-based products such as drywall (also known as plasterboard or sheetrock) and plaster are fundamental materials in building structures, particularly in interior design and finishing. Drywall, made from a core of gypsum sandwiched between layers of paper, is widely used in residential and commercial buildings to create smooth, fire-resistant walls and ceilings. Its lightweight nature makes it easy to install and handle, while its ability to be cut and shaped to fit any space is unmatched.

Plaster, another product derived from gypsum, has been used in construction for centuries. When mixed with water, gypsum powder forms a paste that can be applied to surfaces to create smooth, durable finishes. Plaster is not only used for walls and ceilings but also for decorative elements such as moldings, columns, and arches, contributing to both aesthetic appeal and structural integrity. Moreover, gypsum's fire-resistant properties make it a preferred material for fireproofing, contributing to the safety of buildings.

The Role of Gypsum in Cement Production

The cement industry is another major consumer of gypsum. In cement manufacturing, gypsum is added to clinker, the key ingredient in cement, during the final stages of production. The addition of gypsum helps control the setting time of cement, ensuring that it doesn’t harden too quickly when mixed with water. This process is essential for achieving the right consistency and durability in the final product, making gypsum a critical additive in the production of both regular and specialized cement types.

Without the proper use of gypsum in cement, the material could set too quickly, making it difficult to work with and reducing its strength and stability. Gypsum’s role in regulating the setting time allows construction projects to proceed smoothly and ensures that the cement meets the necessary quality standards.

Gypsum in Agriculture: Enhancing Soil Quality

Gypsum also plays a significant role in the agricultural industry. It is often used as a soil conditioner to improve the structure and fertility of the soil. When applied to soil, gypsum helps break up compacted layers, allowing better water infiltration and root penetration. This leads to healthier plants, especially in areas with heavy, clay-like soils that are prone to waterlogging. Furthermore, gypsum provides essential nutrients, including calcium and sulfur, which are beneficial to plant growth.

In addition to its use as a soil conditioner, gypsum is used in some cases as a pH adjuster. It can help reduce soil acidity, creating more favorable conditions for crop growth. This makes gypsum an invaluable tool for farmers aiming to improve crop yields and quality.

Gypsum in Healthcare: Aiding in Medical and Dental Uses

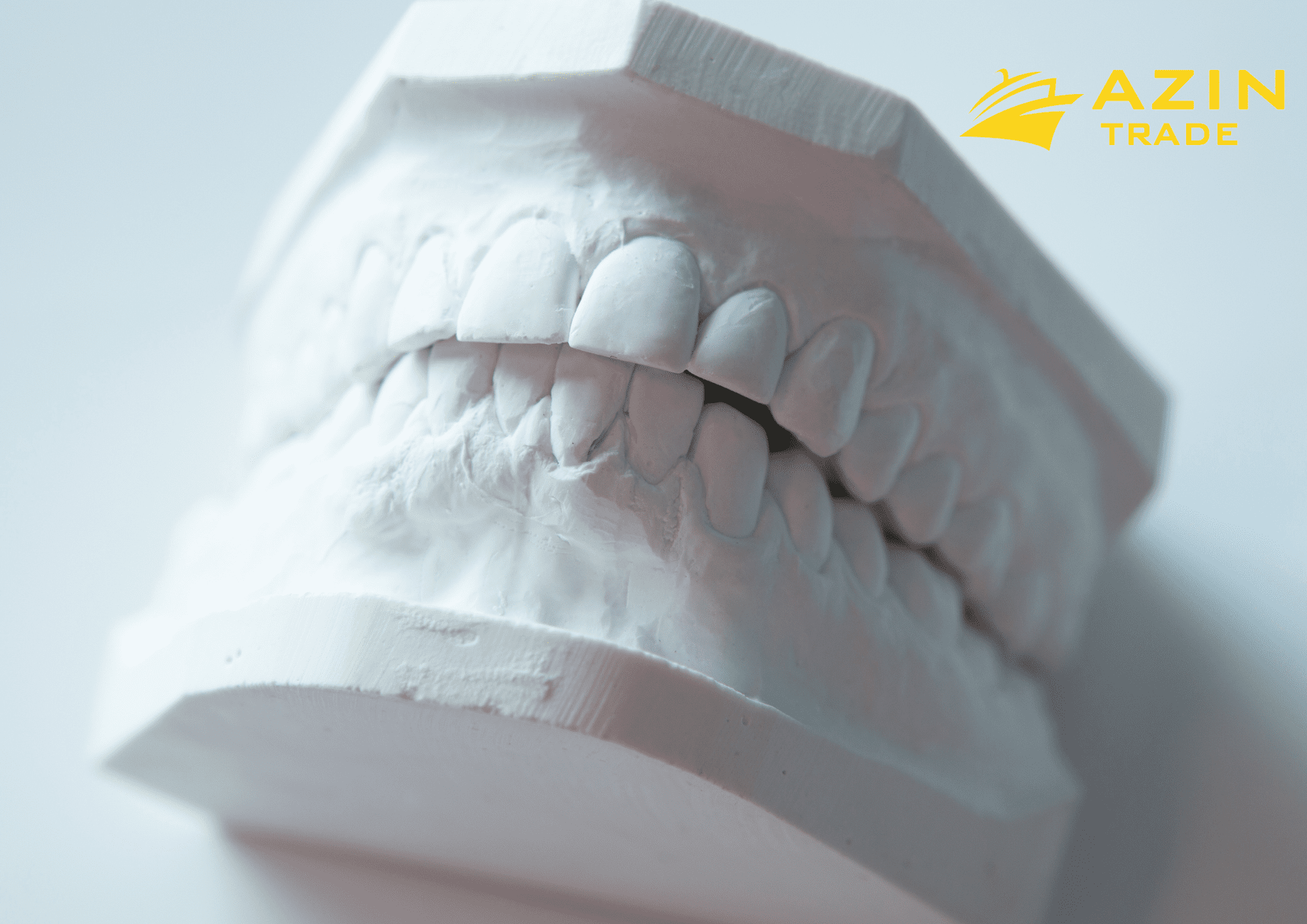

In the healthcare sector, gypsum’s role is primarily focused on its use in medical casting and dental applications. Gypsum-based materials, such as dental plaster and casting plasters, are commonly used to make molds and casts for both medical and dental purposes. For example, in orthopedics, gypsum is used to create plaster casts for broken bones, offering both support and immobilization as the bone heals. The material's ability to harden quickly and form a strong, durable shell makes it ideal for this use.

In dentistry, dental gypsum is used to create molds of patients’ teeth and gums. These molds are crucial for fabricating crowns, bridges, and dentures, as well as for creating accurate models for various dental treatments. The material’s fine, smooth texture ensures that it captures the most detailed impressions, which is essential for creating high-quality dental restorations.

Gypsum in Paper Manufacturing

Gypsum also finds a place in the paper manufacturing industry. In paper mills, it is often used as a filler and coating material. When added to paper pulp, gypsum improves the quality and texture of the paper, making it smoother and more suitable for printing. The use of gypsum as a filler also helps reduce the overall cost of production by increasing the volume of paper produced from a given amount of raw materials.

Furthermore, gypsum’s ability to act as a fire retardant enhances the safety of paper products, making it particularly useful in the production of fire-resistant papers and documents. In addition to its functional benefits, the presence of gypsum in paper helps improve the durability and strength of the final product.

Gypsum in Petrochemical Production

In the petrochemical industry, gypsum plays an essential role as a byproduct of various chemical processes. During the refining of petroleum and natural gas, sulfur is often produced as a waste product. Gypsum is created through the reaction of sulfur dioxide with calcium compounds, capturing the sulfur and preventing it from being released into the atmosphere as a pollutant. This process is vital in minimizing environmental damage and ensuring that petrochemical production adheres to environmental regulations.

Gypsum produced in this way is typically used in various industrial applications, including the production of cement and fertilizers, demonstrating its versatility across different sectors.

Gypsum in Glass and Ceramics

In the glass and ceramics industries, gypsum is used as a fluxing agent. In the production of glass, gypsum helps lower the melting point of raw materials, making the glass manufacturing process more efficient. Similarly, in ceramics, gypsum is used as a mold material for casting and shaping ceramics and pottery. Its ability to form intricate molds ensures that the final ceramic products have the desired shape and finish.

The Environmental Impact and Sustainability of Gypsum

As demand for gypsum continues to rise across multiple industries, its environmental impact remains an important consideration. Fortunately, gypsum is a naturally occurring material that is abundant and relatively easy to mine. Additionally, its use in construction and agriculture helps improve the overall efficiency of various processes, leading to more sustainable practices. Gypsum recycling, particularly from demolition projects, is also gaining traction as a means of reducing waste and promoting sustainability in the industry.

Furthermore, the environmental impact of gypsum extraction and use is relatively low compared to other industrial materials, particularly metals and plastics. This makes gypsum an attractive choice for companies looking to reduce their carbon footprint while still meeting production needs.

Conclusion

From construction and agriculture to healthcare and petrochemicals, gypsum’s wide range of applications demonstrates its importance across industries. Whether it’s improving the quality of cement, enhancing soil fertility, creating medical casts, or refining petroleum products, this versatile material plays a critical role in the modern world. Its continued use and demand will undoubtedly grow as industries evolve, making it an indispensable component of various sectors.

The role of gypsum in these industries highlights the material’s importance and offers insight into the ways it can contribute to innovation and sustainability. As technologies continue to advance, new applications for gypsum may emerge, further cementing its place as a vital resource in the global economy.