clinker

Clinker

Exploring the World of Clinker: A Crucial Element in Cement Production

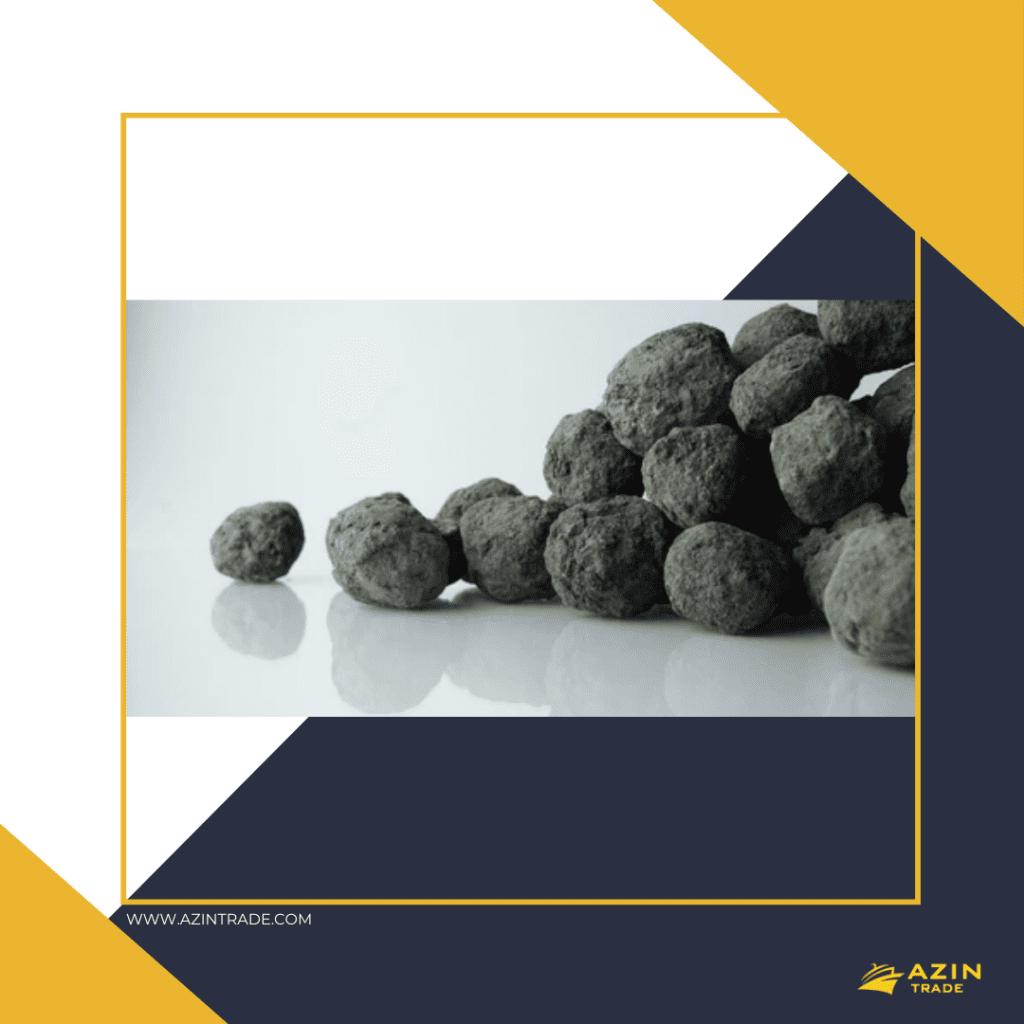

Clinker, the essential precursor to cement, represents a cornerstone in the construction industry. Formed through a meticulous process of heating limestone, clay, and other minerals to high temperatures in a kiln, clinker emerges as small, marble-sized nodules. Its creation involves intricate chemical reactions that fuse raw materials into a durable substance capable of withstanding immense pressure and heat.

Composition and Manufacturing Process

Composed primarily of calcium silicates, aluminates, and ferrites, clinker’s precise composition varies depending on raw materials and production techniques. The manufacturing process begins with the grinding and blending of raw materials, followed by their introduction into a rotary kiln. Temperatures exceeding 1,400 degrees Celsius drive chemical transformations, yielding molten clinker that cools rapidly to form hardened nodules.

Types and Applications

Various types of clinker cater to specific construction needs. Ordinary Portland Cement (OPC) clinker, characterized by high silicate content, serves as the foundation for general construction. Sulphate Resistant Clinker (SRC) excels in environments prone to sulfate attack, offering enhanced durability. White clinker, produced from low-iron raw materials, lends itself to decorative applications due to its bright color.

Environmental Considerations

While indispensable to modern infrastructure, clinker production poses environmental challenges. The energy-intensive process contributes to greenhouse gas emissions, prompting innovations in sustainable practices. Efforts to reduce carbon footprints include alternative fuels, efficient kiln designs, and carbon capture technologies, ensuring clinker’s role in a sustainable future.

Global Significance and Market Trends

Clinker production reflects global economic trends and infrastructure demands. Leading producers like China, India, and the United States drive market dynamics through extensive production capacities and strategic exports. As developing nations invest in urbanization and industrialization, the demand for clinker continues to escalate, shaping trade patterns and cementing its status as a cornerstone of global construction.

Conclusion

In essence, clinker embodies the marriage of tradition and innovation in construction. Its transformative journey from raw materials to hardened nodules underscores its pivotal role in shaping architectural landscapes worldwide. As industries pivot towards sustainable practices, clinker’s evolution remains at the forefront of environmental stewardship and technological advancement.