Cement Supplier & Cement Suppliers – Industrial Bulk Cement Solutions by Azintrade

Introduction

In industrial-scale construction and infrastructure development, selecting a reliable cement supplier is a structural decision, not a purchasing routine.

Bulk cement supply affects compressive strength performance, setting time stability, clinker consistency, and long-term durability of reinforced concrete structures.

Azintrade operates as a professional cement supplier and export coordinator specializing in bulk cement allocation, certified factory sourcing, and controlled logistics management. Unlike generic cement suppliers operating as traders, Azintrade structures its cement supply chain around batch traceability, moisture control, and international compliance standards.

This page explains how cement suppliers operate at an industrial level, how bulk cement export is managed, and why supplier stability determines structural reliability.

Cement Supplier vs Cement Manufacturer: Operational Distinction

A cement manufacturer operates rotary kilns, clinker production lines, and grinding mills.

A cement supplier operates the allocation, storage, logistics, and documentation infrastructure required to move cement from factory to construction site.

As a cement supplier, Azintrade manages:

• Production allocation agreements with certified cement manufacturers

• Bulk cement inventory scheduling

• Warehouse humidity control

• FIFO stock rotation systems

• Jumbo bag and palletized cement loading

• Bulk vessel charter coordination

• Containerized cement export

• Laboratory verification before shipment release

Professional cement suppliers reduce variability between production and application.

Cement Grades Supplied by Azintrade

As an international cement supplier, Azintrade distributes cement compliant with ASTM C150, ASTM C595, and EN 197-1 standards.

Ordinary Portland Cement (OPC)

Typically classified as ASTM Type I or EN CEM I.

Technical parameters verified by Azintrade before bulk cement release:

• 28-day compressive strength consistency

• Initial setting time range

• Final setting time compliance

• Blaine fineness (surface area measurement)

• Loss on ignition percentage

• Insoluble residue ratio

• Alkali content control

Consistency across batches is prioritized over peak isolated test results.

Portland Pozzolana Cement (PPC)

Contains pozzolanic materials improving sulfate resistance and permeability reduction.

Used in:

• Mass concrete

• Marine structures

• High-humidity infrastructure

Sulfate Resistant Cement

Engineered for sulfate-rich soils and underground structural applications.

Every shipment supplied by Azintrade includes a Mill Test Certificate (MTC) linked to a specific production batch.

Bulk Cement Supply Infrastructure at Azintrade

Bulk cement supply requires technical storage discipline.

Azintrade maintains:

• Covered warehouse facilities

• Moisture-controlled storage zones

• Pallet wrapping and sealing procedures

• Aerated silo discharge systems

• Bulk tanker pneumatic loading

• Vessel loading supervision

Cement hydration initiates upon exposure to humidity. Even minimal moisture penetration can reduce compressive strength development.

For this reason, Azintrade verifies storage humidity conditions prior to dispatch.

Bulk cement suppliers without storage control systems introduce structural risk at the procurement stage.

Cement Export & International Logistics Management

As an export-oriented cement supplier, Azintrade structures shipments under Incoterms such as FOB, CFR, and CIF.

Export management includes:

-

Volume allocation confirmation

-

Production scheduling alignment

-

Independent laboratory inspection

-

Bagging or jumbo packaging supervision

-

Port loading rate monitoring

-

Bill of Lading issuance

-

Certificate of Origin processing

-

Freight insurance coordination

Documentation accuracy is critical in bulk cement export operations.

Experienced cement suppliers integrate quality verification with logistics sequencing.

Quality Control & Batch Traceability

Industrial cement supply demands measurable consistency.

Azintrade evaluates:

• Clinker ratio stability

• C3S and C2S phase balance

• Gypsum percentage control

• Soundness testing (Le Chatelier method)

• Setting time deviation tolerance

• 2-day, 7-day, 28-day compressive strength progression

Shipment approval is conditional upon laboratory validation.

Reliable cement suppliers maintain digital batch archives for traceability.

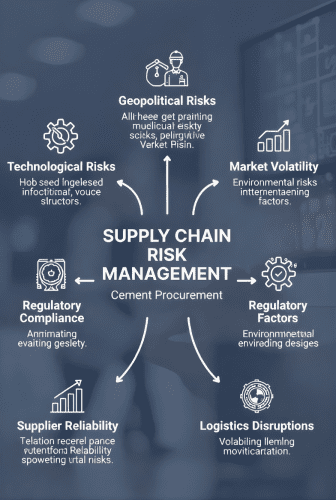

Supply Chain Risk Management in Cement Procurement

Cement pricing and availability are influenced by:

Energy cost fluctuation

Clinker production capacity

Seasonal construction cycles

Freight market volatility

Port congestion

Azintrade mitigates these risks through:

• Multi-factory sourcing

• Allocation forecasting

• Forward freight booking

• Buffer inventory planning

Long-term cement supply contracts reduce procurement exposure to volatility.

Why Azintrade Is Positioned as a Structured Cement Supplier

Not all cement suppliers operate with industrial transparency.

Azintrade integrates:

• Certified sourcing

• Laboratory-backed release procedures

• Controlled storage

• Export documentation precision

• Structured bulk cement logistics

For contractors and distributors requiring stable cement supply, technical transparency and batch consistency matter more than short-term price variation.