Cement Suppliers 2026: Global Supply Chain Changes Explained

The global cement industry is undergoing structural changes in 2026 that are redefining how cement is sourced, produced, and distributed. After years of disruption caused by energy instability, logistics challenges, and regulatory pressure, the cement supply chain is no longer operating under traditional assumptions. In this evolving environment, cement suppliers are playing a more strategic role than ever before.

Understanding how these changes affect sourcing decisions is essential for manufacturers, traders, and large-scale construction buyers.

How Cement Suppliers Are Adapting to Supply Chain Changes in 2026

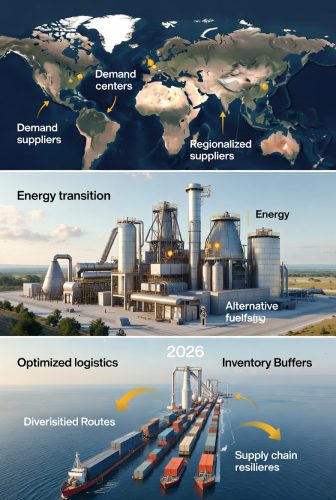

One of the most important developments in 2026 is the shift from globalized supply models toward more resilient and regionally balanced systems. Cement suppliers are increasingly focusing on supply security rather than volume expansion.

Buyers are prioritizing suppliers that can guarantee consistent delivery, predictable lead times, and reduced exposure to shipping volatility. This trend has strengthened the position of regional cement suppliers and reduced dependence on long-distance, price-driven sourcing.

Energy Transition and Its Impact on Cement Suppliers

Energy costs remain one of the most critical variables in cement production. In 2026, cement suppliers that invested in alternative fuels, waste-derived energy, and efficiency upgrades are gaining a competitive edge.

Suppliers with lower energy volatility are better positioned to offer stable pricing and long-term contracts. In contrast, cement suppliers reliant on conventional fuel sources face higher operational risks and reduced flexibility in export markets.

Energy strategy has become a defining factor in supplier selection.

Logistics Resilience and Supply Chain Stability

Logistics disruptions over recent years have forced cement suppliers to redesign their distribution strategies. In 2026, supply chain resilience is a core competitive advantage.

Cement suppliers are diversifying shipping routes, securing long-term freight agreements, and strengthening relationships with port operators. Inventory buffers and flexible loading schedules are now standard practices rather than exceptions.

For buyers, logistics capability is as important as price and quality when evaluating cement suppliers.

Sustainability Regulations Reshaping Supplier Selection

Environmental compliance is no longer optional in 2026. Cement suppliers are under increasing pressure to demonstrate measurable reductions in carbon emissions and clinker intensity.

Large infrastructure projects and institutional buyers now require detailed sustainability documentation as part of procurement processes. Cement suppliers that fail to meet environmental standards are increasingly excluded from international tenders.

Sustainability performance has become a decisive factor in long-term supplier partnerships.

Digitalization and Transparency in Cement Sourcing

Digital tools are transforming how cement suppliers interact with buyers. Real-time shipment tracking, digital documentation, and data-driven forecasting are improving transparency across the supply chain.

In 2026, cement suppliers with advanced digital systems offer faster communication, better demand planning, and reduced operational friction. This shift is strengthening trust and enabling longer-term cooperation between suppliers and buyers.

Digital maturity is now a signal of operational reliability.

Regional Cement Suppliers Gaining Strategic Importance

Regional cement suppliers are benefiting from changing market priorities. Shorter transport distances reduce emissions, logistics risk, and delivery uncertainty.

In many markets, buyers are intentionally shifting volume toward regional suppliers to improve supply security. This trend is reshaping trade flows and reducing reliance on a small number of export-heavy regions.

Regional presence is becoming a strategic advantage rather than a limitation.

What Buyers Expect From Cement Suppliers in 2026

Buyer expectations have evolved significantly. Beyond competitive pricing, buyers now demand consistency, transparency, and technical support.

Cement suppliers that provide reliable quality documentation, responsive communication, and flexible contract structures are viewed as strategic partners rather than commodity vendors.

This evolution favors experienced suppliers with long-term operational stability.

The Strategic Role of Cement Suppliers in 2026

In 2026, cement suppliers are no longer passive participants in the construction value chain. Their decisions directly affect project timelines, cost stability, and regulatory compliance.

The most competitive cement suppliers combine efficient production, resilient logistics, environmental responsibility, and digital capability. These characteristics define leadership in a market shaped by uncertainty and transformation.

Conclusion

The cement supply chain in 2026 reflects a new reality driven by energy transition, sustainability regulation, logistics resilience, and shifting buyer priorities. Cement suppliers that adapt to these changes are strengthening their market position and shaping the future of global cement sourcing.

For buyers and manufacturers, choosing the right cement suppliers in 2026 is a strategic decision with long-term consequences.

FAQ

How is the energy transition affecting cement suppliers in 2026?

The energy transition is pushing cement suppliers to reduce fossil fuel dependency by adopting alternative fuels, energy-efficient kilns, and lower-emission production methods. Suppliers that adapt faster are gaining cost stability and regulatory compliance advantages.

Why are cement supply chains becoming more regional in 2026?

Rising logistics risks, carbon regulations, and freight volatility are encouraging buyers to source cement from regional suppliers. This shift improves delivery reliability and reduces exposure to global shipping disruptions.

What role does sustainability play in choosing cement suppliers in 2026?

Sustainability has become a core requirement rather than a competitive advantage. Buyers increasingly expect cement suppliers to provide emissions data, compliance documentation, and alignment with international decarbonization frameworks.

How do global trade trends impact cement suppliers?

Global cement trade data shows shifting export flows toward regional hubs and diversified supply routes. Cement suppliers are adapting by reducing dependence on single markets and strengthening regional distribution networks.

What should buyers prioritize when evaluating cement suppliers in 2026?

Beyond price, buyers should prioritize supply reliability, logistics capability, environmental compliance, and transparency. Long-term operational stability is now more important than short-term cost advantages.