Grey vs White Clinker: Key Differences, Composition & Export Guide (2026)

Executive Overview

Grey vs white clinker is a critical comparison in the cement industry. Understanding the differences between grey vs white clinker helps manufacturers, contractors, and international buyers evaluate performance, cost, and export potential. This 2026 technical guide provides a detailed comparison of chemical composition, production process, strength characteristics, and export considerations for informed bulk clinker purchasing.

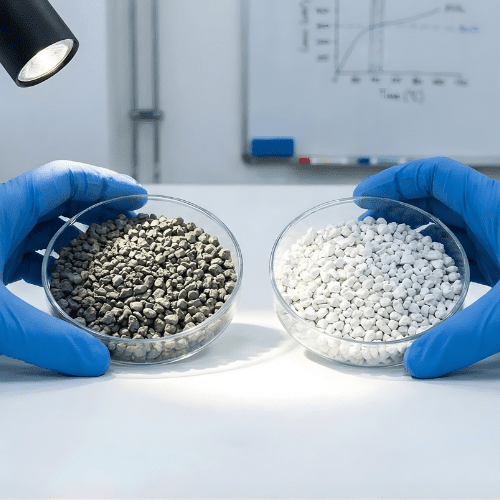

1. Grey vs White Clinker: Chemical Composition

Clinker performance depends on its mineral phases:

-

C₃S (Tricalcium Silicate)

-

C₂S (Dicalcium Silicate)

-

C₃A (Tricalcium Aluminate)

-

C₄AF (Tetracalcium Aluminoferrite)

Grey Clinker Composition

-

CaO: 63–67%

-

SiO₂: 20–23%

-

Al₂O₃: 4–8%

-

Fe₂O₃: 2–5%

-

C₃S: 50–60%

-

C₄AF: 8–12%

Grey clinker owes its color to moderate iron oxide content, making it suitable for mass concrete and general construction.

White Clinker Composition

-

CaO: 65–70%

-

SiO₂: 20–25%

-

Al₂O₃: 4–7%

-

Fe₂O₃: <0.5%

-

C₃S: 60–70%

-

C₄AF: <2%

White clinker requires high-purity limestone and low-iron clay. Its brightness makes it ideal for decorative or architectural cement applications.

2. Production Differences in Grey vs White Clinker

Both types are manufactured in rotary kilns at ~1450°C, but white clinker demands stricter conditions:

-

High-purity raw materials

-

Controlled kiln atmosphere

-

Rapid cooling to maintain whiteness

-

Specialized grinding and handling

Grey clinker production is less sensitive to iron content and kiln control, resulting in lower cost and energy usage.

3. Strength Performance: Grey vs White Clinker

Strength performance is mainly influenced by C₃S content:

-

Grey clinker cement: High early compressive strength, widely used in infrastructure projects.

-

White clinker cement: Comparable strength, optimized for surface aesthetics and decorative structures.

Proper grinding and blending ensure both types meet engineering specifications.

4. Cost Differences Between Grey vs White Clinker (2026)

| Factor | Grey Clinker | White Clinker |

|---|---|---|

| Raw Material | Standard | High-purity |

| Energy Usage | Normal | Elevated |

| Production Control | Standard | Strict |

| Market Price | Competitive | Premium |

White clinker generally commands a 15–30% higher price due to raw material constraints and specialized processing.

5. Export Considerations for Grey vs White Clinker

Grey clinker dominates bulk exports in Iraq, UAE, and Africa due to cost efficiency. White clinker is exported under contract with strict quality verification.

Buyers should request:

-

Complete chemical analysis

-

Loss on Ignition (LOI)

-

Free Lime content

-

Kiln batch traceability

-

Vessel loading documentation

Major shipments from Iran are handled via Bandar Abbas Port in Hormozgan province, a key hub for mineral exports.

6. Applications of Grey vs White Clinker

Grey clinker:

-

Mass concrete

-

Road construction

-

General building projects

White clinker:

-

Architectural concrete

-

Decorative precast elements

-

White cement production

-

Luxury construction projects

Grey clinker addresses volume and cost; white clinker focuses on aesthetics and high-value applications.

7. Environmental Impact of Grey vs White Clinker

Grey clinker production produces larger CO₂ volumes overall. White clinker has higher energy intensity per ton but produces less iron-related byproducts. Modern manufacturers align with ISO 14001 environmental standards to minimize emissions.

8. FAQ

What is the main difference between grey and white clinker?

The primary difference is iron oxide content, which affects color, composition, and cost.

Is white clinker stronger than grey clinker?

Both have comparable structural strength; grey clinker is more common in heavy construction.

Why is white clinker more expensive?

It requires higher purity raw materials, stricter kiln control, and slightly higher energy usage.

Conclusion

The grey vs white clinker comparison clarifies which type suits specific applications. Grey clinker is ideal for bulk infrastructure projects, while white clinker serves high-value decorative purposes. For bulk procurement, choosing a verified clinker supplier ensures consistent quality, proper documentation, and efficient export logistics in 2026.