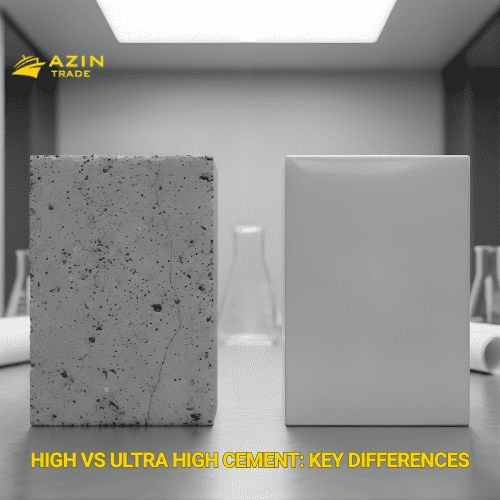

High vs Ultra High Cement: Key Differences

High vs ultra high cement is a crucial comparison in modern construction and structural engineering. Although these two cement types are sometimes confused, they serve distinct technical and practical purposes. Choosing the wrong type can lead to over-specification, unnecessary costs, delays, or reduced performance.

Understanding these differences allows engineers, architects, and contractors to make informed decisions, ensuring long-term safety, durability, and cost efficiency throughout the project lifecycle.

What Is High Cement?

High cement is designed to achieve compressive strengths higher than ordinary Portland cement, typically supporting concrete strengths of 50–70 MPa. Manufacturers improve clinker quality, control fineness, and add small amounts of performance-enhancing materials to reach this strength range.

This type of cement balances structural performance and cost, making it suitable for conventional construction projects.

Applications of High Cement

-

Commercial office buildings

-

Mid-rise residential structures

-

Industrial floors and warehouses

-

Standard precast panels

High cement provides reliable performance where extreme strength margins are not required, while maintaining cost-effectiveness and structural safety.

What Makes Ultra High Cement Different?

Ultra high cement is engineered for extreme structural performance. It can achieve compressive strengths above 80 MPa and, in some advanced formulations, 100–150 MPa. Manufacturers achieve this by optimizing clinker chemistry, particle size distribution, grinding precision, and incorporating supplementary cementitious materials (SCMs) such as silica fume, fly ash, or slag.

Consequently, ultra high cement is ideal for projects where structural failure is not acceptable and safety margins are extremely tight.

Key Advantages of Ultra High Cement

-

Allows slimmer structural sections, reducing material usage

-

Decreases self-weight, improving load efficiency

-

Enhances long-term durability in marine, industrial, and aggressive environments

-

Supports high-performance applications in critical infrastructure

By providing these benefits, ultra high cement meets the demands of super-tall buildings, long-span bridges, offshore platforms, and heavy-load industrial floors.

Strength Comparison in Real-World Applications

While both high and ultra high cement exceed standard cement performance, their real-world behavior differs significantly.

-

High cement: Performs well under moderate to heavy loads but may require thicker sections to satisfy safety requirements.

-

Ultra high cement: Enables thinner cross-sections, reduces self-weight, and improves structural efficiency without compromising durability.

This distinction becomes critical in high-rise towers, long-span bridges, and prestressed concrete systems, where material choice directly affects cost and structural integrity.

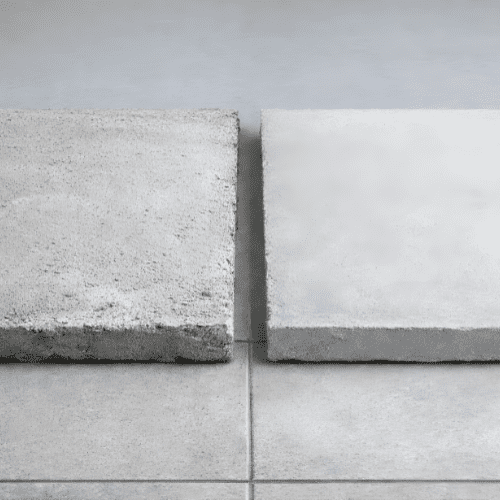

Durability and Environmental Resistance

Durability often outweighs raw compressive strength in importance.

-

High cement: Provides adequate resistance in moderate exposure conditions.

-

Ultra high cement: Offers reduced permeability, superior resistance to chloride penetration, sulfate attack, chemical exposure, and abrasion.

Therefore, projects exposed to harsh climates, aggressive industrial environments, or marine conditions benefit significantly from ultra high cement’s enhanced durability.

Cost vs Performance

High cement generally has a lower upfront cost and is sufficient for many standard projects. However, ultra high cement, while more expensive per unit, can reduce total project costs by:

-

Enabling thinner structural elements

-

Shortening construction cycles

-

Extending service life

-

Minimizing maintenance requirements

Ultimately, the decision should focus on lifecycle performance rather than unit material cost alone.

Practical Guidelines for Choosing the Right Cement

-

Evaluate structural demand: Projects with heavy loads, tall buildings, or long spans often justify ultra high cement.

-

Consider environmental exposure: Aggressive or marine conditions favor ultra high cement.

-

Check material compatibility: Ensure the cement works with local aggregates and chemical admixtures.

-

Verify supplier support: Request certified test results, mix design guidance, and technical documentation.

-

Balance cost and performance: Focus on long-term efficiency, durability, and safety rather than unit price alone.

By following these guidelines, engineers reduce the risk of over-specification while ensuring structural integrity and long-term performance.

Real-World Examples

High Cement

-

Mid-rise residential blocks

-

Office complexes

-

Standard precast panels

Ultra High Cement

-

Super-tall skyscrapers

-

Offshore platforms and marine structures

-

Heavy-load industrial floors

-

Long-span bridge decks

These examples demonstrate that understanding high vs ultra high cement is essential for safe, efficient, and cost-effective construction.

Technical Insights and Performance Considerations

-

Fineness and hydration rate: Ultra high cement is ground finer, improving early strength development.

-

Additives impact: SCMs enhance long-term durability, reduce porosity, and optimize performance.

-

Consistency and quality control: Ultra high cement requires stricter testing and monitoring to ensure reliable outcomes.

Therefore, selecting the right cement type involves considering not only strength but also compatibility, environmental resistance, and supply reliability.

Conclusion

High vs ultra high cement is not about which is universally “better” but about selecting the most appropriate material for each project. Understanding differences in strength, durability, environmental resistance, and cost ensures optimal material selection.

Correct specification aligns cement performance with structural requirements, reduces over-engineering, improves cost efficiency, and enhances long-term durability.

For further guidance, consult the Ultra High Strength Cement pillar guide for comprehensive insights into high-performance cement solutions.