Introduction

Over the past decades, the global construction and industrial materials sector has increasingly recognised the importance of high-purity gypsum rock as a raw material for plaster, drywall, cement and agricultural applications. Among the countries with vast gypsum resources, Iran stands out not only for the volume of its deposits, but especially for the exceptional purity of many of its gypsum formations. This article will explore why Iranian gypsum is among the purest in the world, covering the geological origins, mining and processing practices, key producing provinces, quality-specification data and the implications for international markets.

1. Geological context and reserves in Iran

1.1 Vast gypsum reserves

Semnan Province, Fars Province, Hormozgan Province and other regions of Iran host massive gypsum deposits. According to the US Geological Survey (USGS), Iran’s gypsum production in 2022 was estimated at 16 million tons, representing about 10.6% of world output.

The reserves are reported to be very large; for example, some studies indicate Iran has over a billion tons of gypsum reserves.

1.2 Geological conditions favouring purity

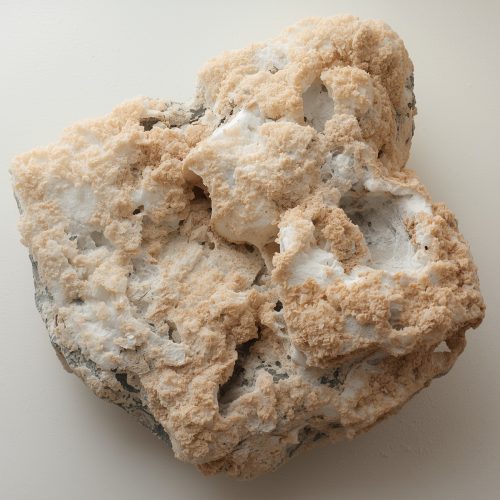

Gypsum (chemical formula CaSO₄·2H₂O) typically forms in sedimentary evaporite environments — when seawater or brine evaporates and calcium and sulfate combine. iranchemicalmine.com+1

In Iran’s case, the presence of thick, continuous gypsum beds in stable sedimentary basins (for example in Semnan) and relatively low levels of contaminant minerals (such as heavy clays, carbonates, or high-chloride salts) give many Iranian deposits a structural advantage in terms of purity. For example, one Persian source claims:

“80% of Iran’s gypsum is produced in Semnan Province … due to the high purity of its mines, making Semnan gypsum synonymous with Iranian gypsum in the international market.

2. Production, quality specification and purity data

2.1 Typical purity figures

Quality data from Iranian suppliers indicate very high gypsum rock and powder purities. For instance, one supplier states natural gypsum powder from Iran with CaSO₄·2H₂O content of min. 97%.

Another source states rock gypsum from Iranian mines has purity greater than 97%

These purity levels compare favourably with many global sources, especially where deposit geology leads to more impurities.

2.2 Key parameters affecting purity

The following parameters are commonly used to evaluate gypsum rock/powder for industrial use:

-

CaSO₄·2H₂O content (higher = better)

-

SO₃ content

-

Moisture content

-

MgO, Cl and other contaminant levels

-

Size / mesh distribution for powder forms

For example, one Iranian product specification indicates: CaSO₄·2H₂O ≥ 97.01%, NaCl ≤ 0.01%, moisture very low.

Low levels of chloride and other salts are crucial, especially for cement-industry use, as chlorides can cause corrosion in steel reinforcement.

2.3 Mining and processing practices enhancing purity

Iranian mines such as those owned by Jonoub Gypsum Company benefit from modern crushing and screening lines, and proximity to export ports (e.g., in Hormozgan )

These logistical advantages allow rapid transport from mine to processing or shipping, reducing contamination risk or weathering. Some plants also produce micronised gypsum powder (mesh 100, mesh 250) for high-spec applications.

Thus, not only are the raw deposits of high quality, but the processing chain supports maintaining that purity through to dispatch.

3. Why Iranian gypsum is among the purest – key drivers

3.1 Deposit geology and low impurities

As noted, the sedimentary evaporite origin and favourable local geology (e.g., minimal intrusion of foreign rocks, favourable stratigraphy) mean many Iranian gypsum beds have inherently high purity. Combined with limited contamination by e.g., iron oxides or heavy clays, this gives Iranian gypsum a competitive quality edge.

3.2 Large scale continuous beds

Larger continuous beds often allow selective mining of high-purity zones, rather than small, fragmented deposits where mixing of lower-quality material may occur. Iran’s large beds (some with tens of millions of tons of reserves) allow such selective production. For instance, one table in Global Gypsum lists Iranian reserves in single mines like 70 Mt for a mine in Fars.

This scale allows cost-effective mining and higher grade output.

3.3 Proximity to export infrastructure

Many of Iran’s gypsum mines are located near the Persian Gulf or major transport/port infrastructure (e.g., near Bandar Abbas). One supplier mentions “the mine is near Bandar Abbas Port so the price is competitive”.

This reduces logistics-related handling and contamination, and shortens time from extraction to shipping, which helps preserve quality.

3.4 Established industry with quality control

Iranian gypsum producers have adopted quality management systems and international standards. For example, Jonoub Gypsum Company claims ISO 9001 and other certifications.

The presence of many modern crushers, screening lines and powder plants—though some older plants remain—supports consistent output of high-spec gypsum products.

3.5 Competitive pricing enabling focus on quality

Because many Iranian gypsum mines produce in large volume and transport cost is relatively contained (due to port proximity), Iranian gypsum can be offered at competitive FOB prices. One supplier states raw gypsum from Iran with 95% purity and very competitive pricing.

This pricing strength allows buyers to pay for higher-quality material rather than settle for lower-spec options.

3.6 Strategic export orientation

Iran’s gypsum industry has an outward-looking export orientation. According to export trade data, Iran exported numerous shipments of gypsum rock/powder (e.g., 676 shipments of gypsum from Oct 2023 to Sep 2024) to 56 destinations.

The need to satisfy external markets with high quality has likely driven producers to maintain high purity standards.

4. Applications of high-purity Iranian gypsum

4.1 Construction & building materials

High-purity gypsum is used to make plaster, stucco, drywall (gypsum board) and other building components. Ensuring low impurities is critical for setting time, strength, consistency and avoiding defects. Iranian producers supply both raw rock and processed powder suitable for such uses.

For example, one Iranian mine/powder plant produces mesh 100 and mesh 200 gypsum powder for plaster. en.irgyps.com+1

4.2 Cement-industry use

Gypsum is used as a setting regulator in Portland cement. High-purity gypsum (with low chloride, low magnesium) is essential to maintain cement performance and avoid corrosion of reinforcement.

Iranian rock with > 97% CaSO₄·2H₂O is well suited for such use.

4.3 Agriculture and soil conditioning

Gypsum is used to amend soils (especially saline or sodic soils) due to its calcium and sulfate content. While less stringent purity may suffice here, high-purity gypsum offers advantages in terms of predictable behavior and minimal contamination.

Iran’s abundant reserves allow supply for such diverse applications.

5. Challenges and considerations

5.1 Mining sector structure & technology gap

Although Iran’s gypsum deposits are high quality, studies show that many plants still use older technology. For example, one study of economics of gypsum production in Iran notes that in 2005, over 70% of gypsum plants were manual operate. scialert.net

This means that while raw purity is high, maintaining consistency and further value-added processing may be constrained in some locations.

5.2 Export restrictions and global competition

Iran’s exports of gypsum have at times been curtailed by sanctions and regulatory constraints, which affects international supply positioning. globalgypsum.com+1

Meanwhile, competing countries such as Oman, China and others continue to expand exports. globalgypsum.com+1

Thus, although Iran has high-purity gypsum, market access and logistics are key to capturing value.

5.3 Quality variability across mines

Not all Iranian gypsum deposits are identical. While some mines produce > 97% purity rock, others may have more impurities or be located in more challenging logistics zones. Buyers should still insist on test certificates, assay reports and independent lab verification.

6. Implications for buyers and the global market

6.1 For buyers seeking high-purity raw gypsum

If your project requires gypsum rock or powder with very low impurities (e.g., for high-performance plaster, special cement or niche industrial uses), Iranian gypsum offers a strong proposition: large reserves, high purity, competitive pricing, good logistics (especially from southern ports).

Key due diligence steps: review mine assay certificates, ensure packaging and handling avoid contamination, check shipment traceability and chain of custody.

6.2 For exporters/industry in Iran

Producers in Iran can leverage the “high-purity” message as a differentiator in global marketing. Emphasising certifications (ISO, ASTM test reports), port-logistics readiness, and competitive FOB pricing will help position Iranian gypsum against competitors.

Potential markets include India (which imports large volumes of gypsum), GCC countries, Southeast Asia and Africa.

6.3 For the global market and sustainability

High-purity gypsum from Iran supports the global construction industry’s need for quality raw materials. Given the push for sustainable buildings and materials with lower waste / better performance, sourcing high-quality gypsum is beneficial. Moreover, the large reserves in Iran mean supply stability.

However, industry stakeholders should also consider transportation emissions, local environmental regulations, and mine rehabilitation to maintain sustainable credentials.

7. Summary & conclusion

In summary, Iranian gypsum is among the purest in the world for the following reasons:

-

Favourable geology and large continuous deposits with inherently high purity

-

High CaSO₄·2H₂O content (often ≥ 97%) and low levels of contaminants

-

Efficient mine-to-port logistics in many cases, reducing contamination risk

-

Established industry with quality control and export-oriented mindset

-

Competitive pricing enabling access to premium-quality material

For buyers requiring high-spec gypsum raw material, Iran presents a compelling source. As long as due diligence on quality certification, logistics and mine, and export conditions are addressed, Iranian gypsum stands as a globally-competitive option.

As the global construction and industrial market evolves, high-purity raw materials will increasingly matter — and Iranian gypsum is well-positioned to meet that demand.