Understanding Portland Cement Clinker: Key Insights and Industry Perspectives

Portland cement clinker is a fundamental component of modern construction, crucial for producing high-quality concrete and mortar. This hydraulic material, defined by stringent standards, plays an indispensable role in the construction industry due to its durability and strength. At Azintrade, we are proud to be one of the largest suppliers of this essential material from Iran, contributing to global infrastructure projects with our top-tier products.

What is Portland Cement Clinker?

Portland cement clinker, often referred to simply as clinker, is a key ingredient in the production of Portland cement. It is primarily composed of calcium silicates, specifically tricalcium silicate (C₃S) and dicalcium silicate (C₂S). According to the European standard ENV 197–14, this material must contain at least two-thirds by mass of these calcium silicates. The remaining composition consists of aluminum oxide (Al₂O₃), iron oxide (Fe₂O₃), and other minor oxides.

The critical parameters for clinker include a mass ratio of calcium oxide (CaO) to silicon dioxide (SiO₂) of no less than 2.0. Additionally, the magnesium oxide (MgO) content is restricted to a maximum of 5.0% by mass. These specifications ensure that the clinker produced meets the required quality and performance standards necessary for effective cement production.

The Production Process

The manufacturing of Portland cement clinker involves a complex process of heating and chemical transformation. Initially, raw materials, which include limestone (rich in CaO), clay or shale (providing SiO₂, Al₂O₃, and Fe₂O₃), are finely ground and mixed. This mixture, known as raw meal or slurry, is then heated in a kiln at temperatures reaching up to 1450°C (2642°F).

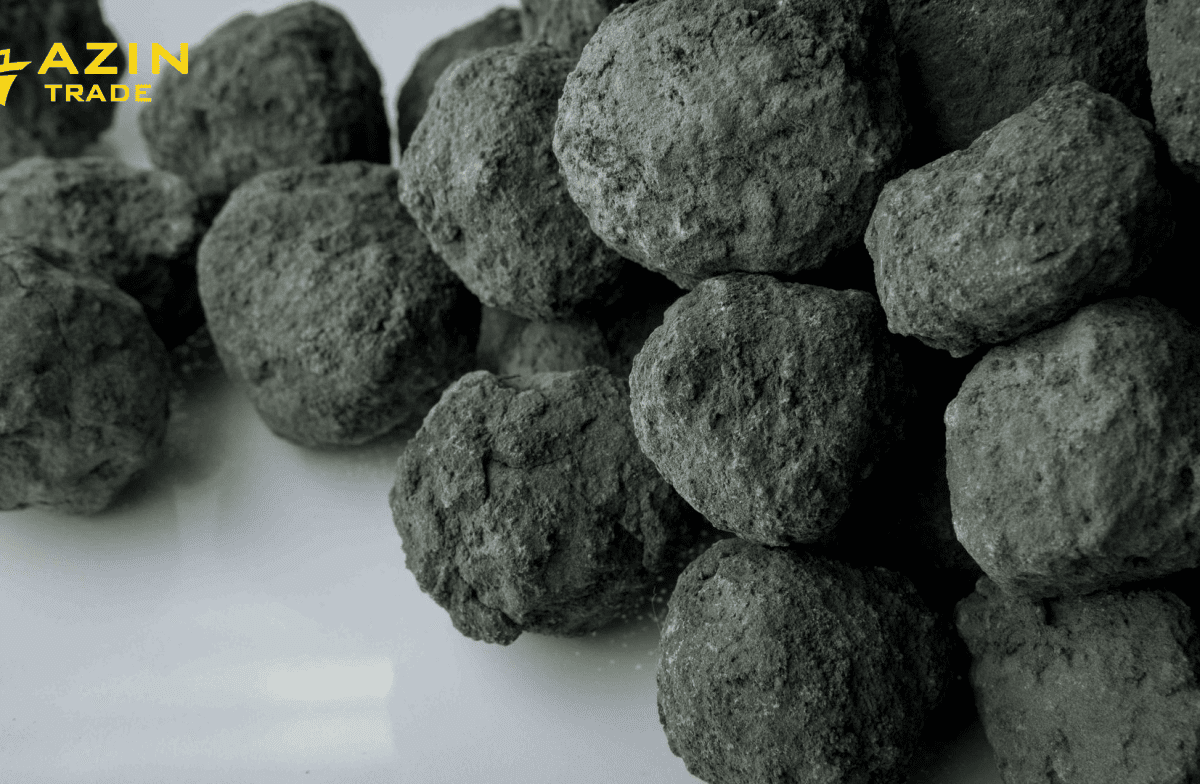

During this heating process, the raw materials undergo sintering—a stage where they partially melt and form clinker nodules. These nodules are then rapidly cooled and ground into a fine powder. The result is a material with the properties required for high-strength concrete, including low solubility, high resistance to weathering, and good workability.

Industry Standards and Definitions

In the United States, the production and characteristics of Portland cement clinker are defined by ASTM C 219-94. This standard describes clinker as "a partially fused clinker consisting primarily of hydraulic calcium silicates." The designation highlights the essential role of hydraulic calcium silicates in ensuring the strength and durability of the final cement product.

Global Supply and Demand

The global demand for Portland cement clinker is substantial, driven by ongoing construction projects and infrastructure development worldwide. Major construction markets, including those in Asia, the Middle East, and parts of Africa, rely heavily on clinker for producing cement used in buildings, roads, bridges, and other infrastructure.

As one of Iran's largest suppliers of Portland cement clinker, Azintrade plays a pivotal role in meeting this demand. Our commitment to quality and reliability has established us as a trusted partner for numerous international clients. Our state-of-the-art facilities ensure that we produce clinker that meets or exceeds global standards, supporting the construction industry’s needs across various continents.

Challenges and Opportunities

The production and supply of Portland cement clinker are not without challenges. Factors such as fluctuating raw material costs, environmental regulations, and technological advancements in production can impact the industry. For example, reducing carbon emissions and improving energy efficiency are crucial areas of focus. The cement industry is actively working on innovative solutions to address these challenges, including adopting cleaner production technologies and exploring alternative materials.

Moreover, as construction projects continue to expand globally, there are significant opportunities for growth. Emerging markets, infrastructure investments, and the demand for sustainable building practices are expected to drive the need for high-quality clinker. At Azintrade, we are well-positioned to leverage these opportunities, ensuring that we remain at the forefront of the industry while contributing to the global infrastructure boom.

Conclusion

Portland cement clinker is a cornerstone of modern construction, essential for producing durable and reliable cement. Its production process, defined by precise standards and specifications, ensures that it meets the high demands of the global construction market. At Azintrade, our role as a leading supplier of this vital material underscores our commitment to supporting infrastructure development worldwide. As we continue to navigate the evolving landscape of the cement industry, we remain dedicated to providing top-quality products that contribute to building the future.