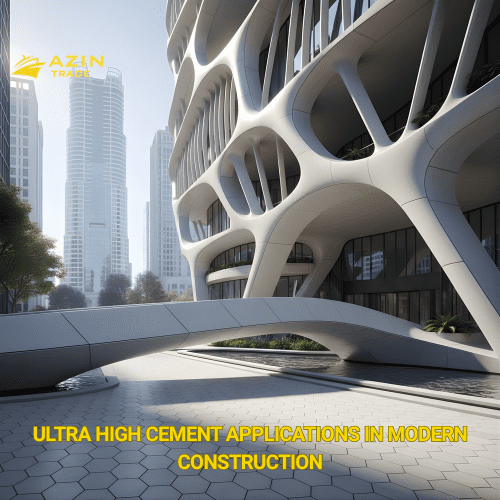

Ultra High Cement Applications in Modern Construction

Ultra high cement applications play an increasingly important role in modern construction as structural demands continue to rise. Engineers and developers now face tighter safety margins, harsher environments, and more ambitious designs. Because of these challenges, ultra high cement has become a key material for projects that require exceptional strength, durability, and long-term performance.

Understanding ultra high cement applications helps professionals choose the right material strategy while avoiding unnecessary cost or over-engineering.

Understanding Ultra High Cement in Construction

Ultra high cement refers to cement systems engineered to support extremely high compressive strength, typically above 80 MPa and often exceeding 100 MPa. Unlike conventional cement, this material focuses on optimized clinker chemistry, controlled particle size distribution, and advanced supplementary cementitious materials.

As a result, ultra high cement applications extend far beyond standard building construction. Instead, they target projects where structural efficiency and durability directly affect safety and lifecycle performance.

Ultra High Cement Applications in High-Rise Buildings

One of the most visible ultra high cement applications appears in high-rise and super-tall buildings. These structures must resist massive vertical loads, wind forces, and, in many regions, seismic activity.

Therefore, designers use ultra high cement to reduce column and core dimensions while maintaining strength. Consequently, buildings gain more usable floor space and improved structural stability. In addition, slimmer elements lower overall self-weight, which reduces foundation demand.

Because of these advantages, ultra high cement applications have become standard practice in modern skyscraper design.

Use of Ultra High Cement in Bridges and Long-Span Structures

Another critical area for ultra high cement applications involves bridges and long-span infrastructure. In these projects, material fatigue, environmental exposure, and load repetition play a major role.

Ultra high cement supports:

Prestressed bridge decks

Segmental bridge components

Long-span girders

Moreover, its low permeability improves resistance to moisture and chemical penetration. As a result, bridge structures achieve longer service life with reduced maintenance needs.

Industrial Flooring and Heavy-Duty Applications

Ultra high cement applications also dominate industrial and heavy-duty flooring systems. Factories, logistics centers, and power plants often operate under constant mechanical stress and chemical exposure.

In these environments, ultra high cement delivers higher abrasion resistance, improved crack control, and better load distribution. Consequently, floors last longer and require fewer repairs over time.

Compared to conventional solutions, ultra high cement applications significantly reduce downtime in industrial facilities.

Marine and Aggressive Environment Applications

Marine and coastal projects represent some of the most demanding ultra high cement applications. Saltwater exposure, chloride penetration, and sulfate attack can quickly degrade ordinary concrete.

For this reason, engineers specify ultra high cement in:

Ports and harbors

Offshore platforms

Coastal protection structures

Its dense microstructure limits water ingress and slows reinforcement corrosion. Therefore, structures maintain performance even in aggressive exposure conditions.

Ultra High Cement Applications in Precast Construction

Precast and modular construction increasingly rely on ultra high cement applications to meet precision and speed requirements. Higher early strength allows faster demolding, while improved flow characteristics enhance surface quality.

Additionally, ultra high cement enables thinner precast elements without sacrificing strength. As a result, transportation becomes easier, and installation efficiency improves.

This trend continues to grow as modular construction gains popularity worldwide.

Performance Advantages Across Applications

Across all ultra high cement applications, performance benefits remain consistent. Strength, durability, and dimensional efficiency work together to improve overall structural behavior.

Furthermore, using ultra high cement often reduces total material volume. Consequently, projects can lower long-term environmental impact despite higher initial material specifications.

Because of these combined benefits, ultra high cement applications align well with modern sustainability and lifecycle design strategies.

When Ultra High Cement Applications Make Sense

Not every project requires ultra high cement. However, ultra high cement applications become the correct choice when structures face extreme loads, aggressive environments, or strict durability requirements.

In contrast, conventional or high-strength cement may suit standard buildings with moderate demands. Therefore, engineers should always match cement performance to actual project needs.

Clear specification prevents both underperformance and unnecessary over-design.

Conclusion

Ultra high cement applications in modern construction continue to expand as engineering challenges grow more complex. From high-rise buildings to marine infrastructure and industrial floors, this material enables safer, more efficient, and longer-lasting structures.

By understanding where ultra high cement applications provide real value, professionals can make informed decisions that balance performance, cost, and durability over the full lifecycle of a project.